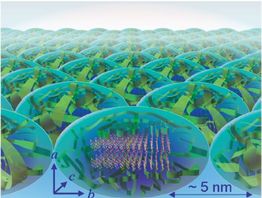

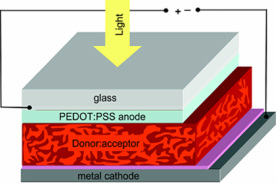

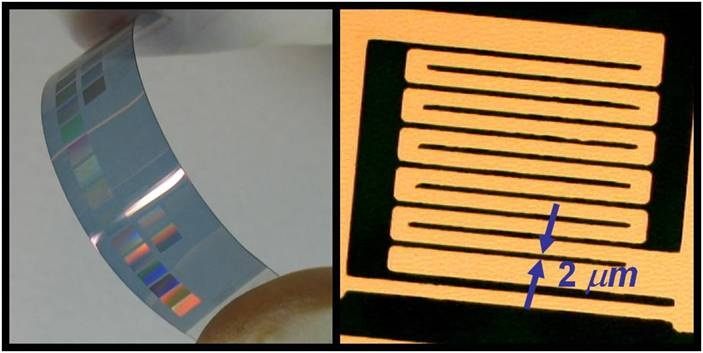

| PEDOT:PSS is a polymer mixture containing two main components: poly(3,4-ethylenedioxythiophene) (PEDOT) crystals encased in chains of hydrophilic poly(4-styrenesulfonate) (PSS). As is shown in the picture at left, these two ionomers form miscelles at the nanometer scale. What does this benefit? If you make touch screens, photographic fim, capacitors, or organic photovoltaics then you may be very interested, because this polymer mix has the potential to serve as a highly conductive (>1000 S/cm @ room temperature) material in any of your applications/devices for relatively cheap. |

Up until March of this year however, the finer details of how and why this polymer mixture was so conductive were not well understood. Researchers Takano et. al. used small angle x-ray scattering (SAXS) and wide angle x-ray scattering (WAXS) at BL40B2 of the SPring-8 research facility in Japan to probe the relationship between this polymer's structure and its conductivity. It was found that the more highly oriented and crystallized the PEDOT crystals were within the PSS shells, the more conductive the thin films were.

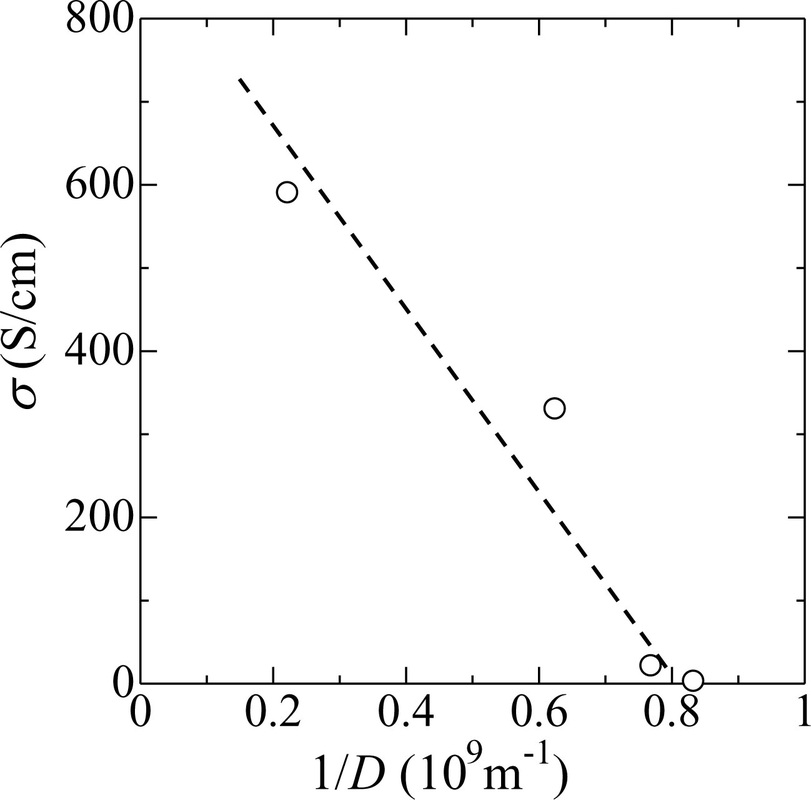

| It was also determined that adding different solvents to the PEDOT:PSS mixture before drying aided in crystal formation. The graph at left plots the inverse of the crystal size, D, with sigma, the conductivity of the sample. It should be noted here that the general procedure for making these thin films was degassing of the water/solvent/PEDOT:PSS dispersion in a vacuum, drying at set temperature for several hours, and then hot drying at a higher temperature for a shorter time to remove the liquid and solvent. In an industrial application, a dispersion is applied to the substrate via spin coating, and then heated to remove the excess water/solvent. |

In addition to the effect of the crystallinity size of the PEDOT on the overall conductivity of the polymer, a more detailed relation between structure of PEDOT crystalline and its electric conductivity is currently being

investigated. The full paper covering the initial research on the structure, and the effect of added solvents, was published in Macromolecules 2012, Issue 45, pp 3859-3865 and can be accessed with subscription here.

investigated. The full paper covering the initial research on the structure, and the effect of added solvents, was published in Macromolecules 2012, Issue 45, pp 3859-3865 and can be accessed with subscription here.

RSS Feed

RSS Feed